Our products

Rare earths are a group of 15 elements in the periodic table known as the lanthanide series. The use of the term ‘rare earths’ is somewhat misleading as the elements are not particularly rare in nature, however due to their geochemical properties, rare earths are dispersed and not often found in concentrated clusters to make them viable to mine.

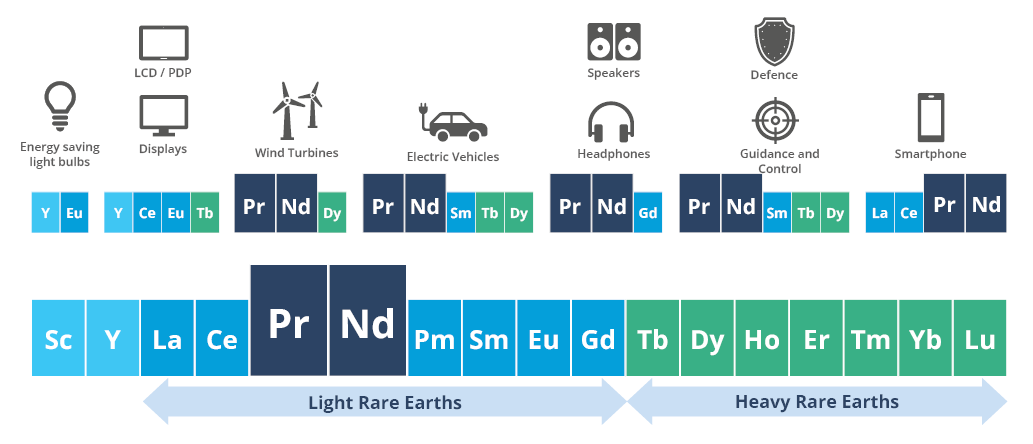

Rare Earths make the technology we use in everyday life possible from medical applications to digital devices and increasingly in the development of humanoid robotics. Their magnetic, phosphorescent, and catalytic properties make them essential for the continued evolution of technologies used in modern society.

Each rare earth deposit has its own unique suite of minerals and due to their high demand in the manufacturing of magnets, the most valuable rare earths include neodymium (Nd), praseodymium (Pr), dysprosium, terbium and samarium.

Each rare earth deposit has its own unique suite of minerals and due to their high demand in the manufacturing of magnets, the most valuable rare earths include neodymium (Nd), praseodymium (Pr), dysprosium, terbium and samarium.

Role of rare earths in the energy transition

An energy system powered by clean energy technologies differs profoundly from one fuelled by traditional hydrocarbon resources. Solar photovoltaic plants, wind farms and electric vehicles generally require more minerals to build than their fossil fuel-based counterparts.

A typical electric car requires six times the mineral inputs of a conventional car and an onshore wind plant requires nine times more mineral resources than a gas-fired power plant.

A typical electric car requires six times the mineral inputs of a conventional car and an onshore wind plant requires nine times more mineral resources than a gas-fired power plant.

Since 2010, the average amount of minerals needed for a new unit of power generation capacity has increased by 50% as the share of renewables in new investment has increased.

NdPr are used in over 90% of manufacturing of NdFeB or permanent magnets. These are the strongest magnets available and are key to the efficient conversion of electrical energy into motion.

These permanent magnets are the enabling technology for the widespread electrification of transport, as well as wind turbines for renewable energy.

NdPr are used in over 90% of manufacturing of NdFeB or permanent magnets. These are the strongest magnets available and are key to the efficient conversion of electrical energy into motion.

These permanent magnets are the enabling technology for the widespread electrification of transport, as well as wind turbines for renewable energy.

Electrifying the automotive sector

By 2040, anticipated global rare earth magnet demand is forecast to outstrip supply by the equivalent of 18 times the projected NdPr output of Yangibana. As the dominant EV motor technology, sintered NdFeB magnets (rare earth magnets) have more than 90% market share among leading automotive original equipment manufacturers.

3,400tpa

NdPr production equivalent from Yangibana Project

55 million

Number of electric vehicles Yangibana will supply over 17-year mine life

1.2bn tonnes

Reduction in carbon emissions (compared to internal combustion engine)

Capitalising on a global supply deficit

8.12%

Compound annual growth rate for permanent magnets

54%

Percentage of rare earth oxide demand for electric drivetrains and wind energy by 2030

18x

Project NdPr oxide output from Yangibana needed to meet forecast supply gap in 2040

Fuelled by the global transition to clean energy, demand for permanent magnets used in electric vehicles and wind turbines is forecast to growth at a compound annual growth rate of 8.12% by 2030.

Electric drivetrains and wind energy is expected to represent 54% of rare earth oxide demand for magnets by 2030, with electric vehicle demand to growth significant as governments ban the sale of the traditional internal combustion engine. In addition, wind power has been identified as the fastest growing renewable energy technology by the International Renewable Energy Agency with installed capacity to grow around two times through to 2030.

Other demand sources for these magnets include the growing areas of humanoid robotics, consumer electronics, industrial applications and air-conditioning.

As a result, it is expected that the demand for rare earth elements – in particular NdPr – will exceed current production rates by 2025, resulting in a sizeable supply gap growing to 2040, representing around 18 times the projected NdPr oxide output of Yangibana. New and more diversified supply sources will be vital, with long project development lead times raising questions around the ability of supply ramp up.

With first concentrate from Yangibana expected in early 1H/2027, the project is well-timed to start meeting this increase in demand.

Electric drivetrains and wind energy is expected to represent 54% of rare earth oxide demand for magnets by 2030, with electric vehicle demand to growth significant as governments ban the sale of the traditional internal combustion engine. In addition, wind power has been identified as the fastest growing renewable energy technology by the International Renewable Energy Agency with installed capacity to grow around two times through to 2030.

Other demand sources for these magnets include the growing areas of humanoid robotics, consumer electronics, industrial applications and air-conditioning.

As a result, it is expected that the demand for rare earth elements – in particular NdPr – will exceed current production rates by 2025, resulting in a sizeable supply gap growing to 2040, representing around 18 times the projected NdPr oxide output of Yangibana. New and more diversified supply sources will be vital, with long project development lead times raising questions around the ability of supply ramp up.

With first concentrate from Yangibana expected in early 1H/2027, the project is well-timed to start meeting this increase in demand.